Jim Logue's 1954 Ford

1954 Ford Convertible owned and restyled by James "Jim" Logue of Long Beach, California. Named "The Fabulous X54," Jim's Ford is known as one of the first cars that used hydraulic lifts to alter the ground clearance. By pressing a button, the car could be raised or lowered 1-6 inches by utilizing a hydraulic system built from aircraft surplus parts. Jim's Ford is the first known custom car to be fitted with hydraulic lifts on all four corners, and it might be the very first custom to ever to incorporate this groundbreaking modification.

Contents

- 1 Inspired by Barris Kustoms

- 2 Fiberglass and Cardboard

- 3 Homemade Bondo

- 4 Reversed Engineered Hydraullic Suspension

- 5 Hydraullic Lifts Up Front

- 6 Lifts and Air Bags in the Back

- 7 Learning From Scratch

- 8 Roof Off and Wraparound Windshield

- 9 Custom Hinges

- 10 Drafted

- 11 Paint. No Time For Flames

- 12 The 1959 National Roadster Show Debut

- 13 The Fabulous X54

- 14 The Clyde Giraldo Memorial Award

- 15 Thanks Dad

- 16 Bothered by the Cops

- 17 Family First

- 18 First and Last Custom

- 19 One Man Show

- 20 The First Lifted Custom?

- 21 Rescued by Andy Lodi

- 22 Sold to Bryan Robinson at Bellflower House of Style

- 23 Magazine Features and Appearances

- 24 References

Inspired by Barris Kustoms

Jim was born on October 1st, 1935. He describes himself as a loner with a passion for engineering. Jim grew up in Long Beach, and he got interested in customs after seeing all the cool cars that were parked in front of Barris Kustoms in Lynwood; “George and Sam Barris had a shop in Lynwood, and my parents used to drive by it on Atlantic when I was a kid. We drove by there often, and I told them to slow down so I could see the cars that were parked in front of the shop. The shop was set back, and they had a parking lot in front. When they had finished a build, before the owner came to pick it up, they put the car on display on the parking lot as advertisement. Seeing chopped 1949, 1950 and 1951 Mercurys in front of the Barris shop got me interested in customized cars, and that’s how I got the idea of building my car,” Jim told Sondre Kvipt of Kustomrama in 2018.[1]

Fiberglass and Cardboard

Jim's father bought the Ford brand new in 1954. A year later he crashed it, and Jim bought the remains so he could turn it into a custom; “It was a business coupe. The cheapest Ford you could get. My dad smashed it up, so I restyled the front end on it back in 1955. I was working at General Motors in South Gate the time, and reworking the car was just my hobby.” Jim earned 2 dollars an hour at GM. He planned to go to Douglas Aircraft, but GM paid twice as much. “I worked at the assembly plant where they built Pontiac, Oldsmobile, and Buicks.” The Ford was Jim’s only mean of transportation, and he drove it while he was working on it. “I had an idea. At the time they were building the first Corvettes out of fiberglass. You could also get some patch kits for repairing and replacing rusted body panels, so I got the idea of building my own fenders in fiberglass. I bought 1955 Mercury headlight rings. I liked those. I then used grey thick cardboard that I formed after the headlights rings. My dad was a furniture upholsterer, and the cardboard came in sheets.” The modified front end was then fitted with a 1955 Cadillac bullet front bumper. “I used a 1956 Cadillac crossbar that I fitted between the bumpers.” The first iteration of the car ran a stamped out square mesh grille. “It was out of sheet metal and painted black. I ended up using 1956 Chevrolet Corvette grilles. The Corvette had 13 teeth in it, and I had 20 some teeth in it across the whole front.” Jim left the mesh in after he installed the Corvette teeth so you couldn’t see behind it. “I also put the mechanism for the headlights behind the fender before I cut through the housing. I made my own knobs so I could reach under the fender and turn these to adjust the headlights. It looked a lot sleeker molded all in!”[1]

Homemade Bondo

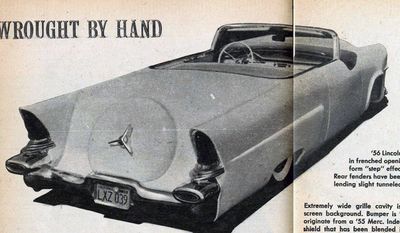

Each year Jim worked on a separate part of the car. After completing the front end, he began restyling the rear. “I never did a drawing or anything on it. It was all in my head.” The rear portion of the body was a complete hand built one-piece construction with all the seams filled in. “I extended the fins 12 inches to fit 1956 Lincoln tail lights. The fenders were originally curved and rolled in making the back end look narrower, so I ran them out straight. I used a 1949 Buick rear bumper that I cut down in the middle.” Jim fitted the bumper with 1956 Lincoln exhaust tips. The exhaust ran through the trunk, over the wheel wells. “The biggest problem back in those days was that they didn’t have bondo yet. I had to make my own bondo. When I made the fiberglass off the cardboard onto the metal fenders, the problem was when the sun was beating down on it it would show the cloth pattern. It didn’t show right away, but after a period of time.” Jim made his own bondo from the sanding dust from the epoxy and the glass mat. “Then when I went over the whole thing. It didn’t show the cloth pattern. The Corvette didn’t show the cloth pattern because they didn’t use cloth. They used particles that they called matting. The matting is little pieces glass, chopped up and when they fiberglassed over that, you didn’t see the pattern of the cloth. I molded the trunk all in, made the trunk lid lower and used a regular trunk lid. I was then gonna draw a line and cut it all out, but I never got that far. I could still access the rear trunk, but I had to do it from under the tarp that covered where the rear seats should be.” A molded-in continental-kit was installed to dress up the rear end. A 1957 Oldsmobile hubcap spinner was installed on the "Connie Kit".[1]

Reversed Engineered Hydraullic Suspension

In 1956 Jim almost got killed when a whole load of bumpers fell over at the GM plant. He took off running and the top bumper hit him in the elbow. After the accident, Jim began working for North American Aviation where he was put in the experimental department. Jim was driving the car for three years, working on each end of it. In 1957, after he had restyled the front and rear end he began working on the hydraulic suspension. The same year a law was part by Governor Brown against all the lowered cars that had started to pop up all over California. The law, named the California Vehicle Code 24008, outlawed any car having any part of the car lower than the bottom of its wheel rim. “They used to have a rollerskate that they would roll under your car with a stick to check the clearance,” Jim remembers. He got the idea for the hydraulics from a Citroen. Citroen first introduced hydropneumatic suspension in 1954, on the rear suspension of the Traction Avant. The first four-wheel implementation was in the advanced DS in 1955. “Citroen used hydraulics to raise the car and go off-road. It was made to raise, so I did some reverse engineering to make it go low.” Jim thought of hydraulics to make the car practical on the street. “I didn’t have no money, so I used second-hand hydraulic parts from Palley Supply Company.” Palley’s was a war surplus store that sold hydraulic parts. “They had books on it, catalogs on how much, how big, how much stroke, and all this. I couldn’t buy hydraulic cylinders that would stick out the hood, so I had to do measuring and buying things they had that worked. I didn’t know what the catalog numbers were or anything, I just bought stuff I knew that I needed, pumps and everything.”[1]

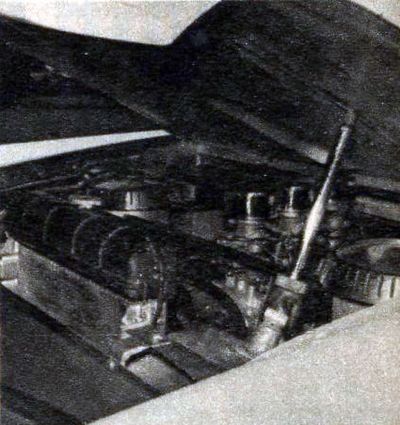

Hydraullic Lifts Up Front

The body on Jim's Ford was the same as the 1952 model. The 1954 Ford came with ball joint suspension and an overhead valve engine, and he wouldn’t have been able to install lifts up front if it had the same body on an earlier frame. Jim C’ed the frame before he cut out the front pockets for the coil spring to go up inside. “I welded sleeves in there so the spring would go up inside with the hydraulics up on top in the engine compartment. If you see under the hood, you see these big round tanks. They weren’t tanks, but that’s where the hydraulic cylinders were inside. As the car went up, I had to have them hinged, because of the angle to the spring when it goes up into the pocket from the A-frame. The tank was next to the radiator up front because it didn’t take that much fluid to fill up the cylinders. They weren’t that big in diameter. Probably 3 inches. It wasn’t a round tank. It looked more like a small suitcase.”[1]

Lifts and Air Bags in the Back

“Most cars had leaf springs in the back those days, including mine, so I cut into the trunk before I installed these overload springs with rubber air bladders inside. If you put air in the bladder, it would go in between the leaf springs, and you could make any stiffness you wanted to. I then put a cylinder who went down to the bottom of the pad on the leaf spring. I took the bottom two leaf springs out, the short ones that stiffen it, because I was using the coils with the air cylinders on top with the hydraulics there too and a cylinder between so I could lower and raise the car from the dash. There was no way I could use a hydraulic cylinder on a leaf spring, so that’s why I used the coil springs up in the trunk. I made guides, steel sleeve guides. It ran bearings and then the hydraulic was under that going to the leaf springs. I wanted it to ride stock, but I wanted it down when it was down. I wanted it to react like a regular car. It rode well.” The electric motors in the aircraft that drove the pumps were 24 volts, but Jim used 12 volts. “I couldn’t afford more than two batteries. It ran slower, but that was OK because I didn’t want it to run too fast up and down.”[1]

Learning From Scratch

Up front, Jim ran into problems when he raised and lowered the car, and the springs went into the buckets that they sat in at the top; “What happened was when the car was raised and lowered at a certain angle, like on a curb, I had problems that it wouldn’t go up and down smoothly. It would hang up on one side, and then the other side would catch up, and then the other side. It didn’t want to go up and down evenly.”Palley's had a valve that would divide the hydraulic fluid to each side, so it didn’t make any difference if one side was lower or hung up. The back didn’t have this problem. “I was learning from scratch about hydraulics, and I used a pump-driven electric motor because I wanted to be able to run the lifts when I had the car at shows. In the shows you had to disconnect the battery in the engine compartment, because of fire. But I had another 12-volt battery in the fender well, just behind the passenger door. In the upholstery, there was a small door where I could get it in and out. I could raise and lower it off that battery, and they couldn’t see it. When I first worked on hydraulics on my car, I didn’t know about relief valves, A relief valve is a dump that steers fluid back to the tank if it’s overloaded. I didn’t have any problems with overloading because I ran it at 12 volts. I was probably lucky that I did that.” A hydraulic cylinder was also installed to open and close the hood from the dash. The backend had more stroke so that Jim could raise the back bumper higher than stock. Up front he only had so much distance; “I could go up to stock, and then down low. The lowest point on the car was a cross-support under the engine. I made the knobs and everything for the hydraulic valves because it was all mechanical. I had to make my own switches, levers, and handles. I had round handles, but I had a little rod running down through the handle so I could get leverage to turn it because it was all mechanical, hydraulic valves.”[1]

Roof Off and Wraparound Windshield

After the car had been lifted, Jim decided to cut the roof off. “I had the windshield cut. Twice. Then I decided, No, I want to put a wraparound windshield in it. Cars were starting to come out with wraparound windshields in 1954. Ford came out with their wraparound windshield in 1955, but the 1957 windshield went around more than the 1955, so I thought "Yeah! I want to put a 1957 windshield in it!” Jim’s dad had a brand new 1957 Ford Ranchero, so he measured how it would fit on his Ford. It fit well, so he knew he had to do that. “Back in those days I was a young kid without any money, so I got a burned out 1957 Ford convertible. I took the dash, windshield section, and firewall from that car. The paint was all gone, and it was rusty. I didn’t want to cut the windshield, so I ended up sculpturing it into the body. I wanted to keep it as a standard convertible windshield so I wouldn’t run into any problems in case it got messed up. It wasn’t easy to cut the windshields down in those days.” Jim had to get another car when he cut the top off. “During the build, I made sure my neighbors were taken care of, so I helped them fix brakes and stuff on their cars to make sure they wouldn’t complain about me working until 3 o’clock in the morning sometimes.”[1]

Custom Hinges

Jim cut the middle of the hood out and lowered it. Then he curved it so he could see over the hood. He put a scoop in the back of the hood that he dressed up with chromed teeth from a 1955 Mercury. “I made my own hinges because the hydraulics wouldn’t have worked on a double action hinge. I built the whole cowl section, and you can see that I sculptured it into the body lines. I decided on what I was going to use, but then I had to make it work.” Jim also rebuilt the engine in the car. It was the first engine he rebuilt himself, and it was hopped up with a three-carb intake manifold.[1]

Drafted

The car was built with intentions of displaying it at the Oakland Roadster Show in February of 1959. “Once I cut the roof off I had to get going in order to complete it for the show. Then I got drafted into the service. They drafted me the day before my birthday, October 1, 1958. I was 22, and in those days they didn’t draft you if you were 23, but they got me the day before I turned 23,” Jim chuckled. When Jim was drafted, the build was completed outside, and he had built front seats for the car from scratch. After Jim lowered the windshield, he had to shorten the steering. If he didn’t shorten the steering, the steering wheel would have been at the top of the windshield. With the shortened steering, a regular bench seat would have hit the bottom of the steering wheel and there would have been no room for legs. “I built the seats from scratch because I wanted them down on the floor. I was long legged and tall, and a regular bench seat would have been way too high for me. In those days the only cars that had those kinds of bucket seats were the Corvettes and the Thunderbirds. That’s where I got the idea for the seats. I didn’t have time to do the backseats. My dad upholstered furniture, so he upholstered the car for me. I painted it, and I did everything except for the seats. I really wanted to do the seats too, cover em, but I didn’t have the time trying to get the car painted and all that stuff.” The seats were upholstered in white and gold Boltavex material.[1]

Paint. No Time For Flames

Worried about being kidnapped for secrets Jim quit his job at the experimental department at North American Aviation. He was only at the new job for a short time before he was drafted and he ended up taking out time in order to get the car ready for the National Roadster Show. “I gave the Ford 40 thin coats of lacquer, which I wet sanded in between with 600 grit paper. That was the finest paper you could get back then. Then I used rubbing compound to remove the scratches from the sanding. I finished it off with cornstarch. Cornstarch was finer than the rubbing compound. I was gonna do flames on it as well, but I never got to that either! After we painted the car, we painted clear lacquer all over it to give it depth. A lot of coats.”[1]

The 1959 National Roadster Show Debut

Jim was stationed at Fort Ord for five months. Fort Ord was an Army post on Monterey Bay of the Pacific Ocean coast in California, 350 miles north of Long Beach, so his dad hauled it up there for the National Roadster Show in Oakland. “Being drafted in the Army I couldn’t finish the car completely. When I left for Fort Ord, it still needed to be wired under the dash, and I had to wire the lights and get the windshield wipers working. Luckily for me, dad hauled it up to Oakland on a flatbed. If it wasn’t for him, nobody would ever have known anything about my car. Dad drove it to where I was at. The car was covered, but I remember the guys at the base saying ”Hey, there’s your car,” because they could see that there was a low car underneath it. It was Friday, and the show was going to start the next day.” Back then the show lasted from Saturday and out the week to the next weekend. “Some guys wanted to go with me so we could clean it and polish it up. On the way over we had a flat tire on the trailer. There were four wheels on the trailer, and we didn’t have a replacement tire with us. Just by luck, there was a little one-man gas station by the road. The fellow at the gas station found a tire at the back of the station that we could put on. My dad drove a 1958 Dodge Royal Lancer. We were five guys in the car, and with the car on the trailer, we got there at 3 o’clock in the morning because we couldn’t drive it faster. All the cars were inside the building when we arrived, but when they pulled the cover off so they could see the car, they made guys pull their cars so I could get the Ford through to the front.”[1]

The Fabulous X54

Jim and his helpers got the car up to the front. They cleaned it up so it was all ready for the show and Jim remember that when people started coming into the show in the morning the car was sticking out as something else; “It didn’t look like what we were used to in those days. A lot of people thought my car was made out of a Packard, but it wasn’t, because I couldn’t afford that! I couldn’t even afford a Ford,” Jim laughs. “My was the cheapest model. A business coupe without a back seat. It had a V8 though. The model with the six in was actually cheaper! I called it the X54, and in the shows, it was called the Fabulous 54. There was a TV show called "The Fabulous 52", and I thought “I’m gonna call it the Fabulous 54.” My dad then had an idea about putting an X in front of the 54, so it was called the Fabulous X54. My dad was a sign painter, and he painted up some signs for me for the show.”[1]

The Clyde Giraldo Memorial Award

The following week Jim was on a train to Fort Bliss in El Paso, Texas, so he couldn’t be there for the award ceremony. “My mom flew in from Long Beach. My dad was already there because he had to haul the car back home.” Jim won “The Clyde Giraldo Memorial Award” with the car, for contributing the most to the automobile industry. This was the first year the award was given out to tribute the well know Bay Area sports writer Clyde Giraldo.”[1]

Thanks Dad

Jim’s dad knew the guy that ran the National Roadster Show, and he helped Jim getting the car in pictures and magazines. Pat Brollier photographed the car for a featured story in Custom Cars Magazine about the time Jim was drafted. “My dad did all that because I was in the darn Army! Dad had a ball showing it off! I was drafted for two years, and I only got to show it at two shows myself during that period. One of the shows was the Renegades Long Beach Motorama. I was there for that one. After the show, we were going to haul it up to Las Vegas for the Rod & Custom Autorama. I was invited along with George Barris and another guy. If I went up there, I was guaranteed a trophy, even though there was no contest. I went up there. We were gonna haul it up on a trailer, but the trailer that we rented wasn’t balanced right, so I drove it up instead. We had to drive two cars, and my parents drove the custom car home from Las Vegas. My dad said a cop was pulling him over and gave him a ticket for not having a front license plate on it. Dad went to court on that, but the judge didn’t fine him at all because he took the back license plate and placed it up front. Then he took a polaroid picture to prove that there was a front license plate on it. There were no problems in court, and the judge dismissed it.”[1]

Bothered by the Cops

After the National Roadster Show, Jim dressed the car up with a rib stainless steel plate from a 1958 Chevrolet Impala on the bottom of the rocker panel. He got out of the army in 1960, and he parked the custom about a year later. “I used the car after I returned from the Army, but I never finished it off. One time I had parked it on a grass parking lot my dad had. I had the car all the way down, and I sat in the grass beside it to watch it. I didn’t have a top on, and I didn’t want anyone to vandalize it. A motorcycle cop pulled up there, and he was looking from the sidewalk, back about ten parking spaces. He pulled back behind my dad’s building, and he was waiting for me to get out because he probably wondered about how I could get out of the driveway right. He waited behind the building, so he couldn’t see me raise the suspension from the dash. I raised it higher than stock before I pulled out of there and made a right-hand turn. He’s behind me, in front of the building, and he’s standing there with his hands on his hips, kinda like huhhh! The look on his face was funny and I had a ball with that.” The cops were on Jim, and they would stop him because he was driving around too low. “Having an electric motor and one battery, having to raise and lower it all the time I finally couldn’t raise it one time, and they nailed me on that so I went to court.”[1]

Family First

Out of the Army, Jim had to get a full-time job. He eventually got married and had to get a house, so he never did finish the Ford up completely. “I was so busy at the time, it wasn’t done, and I didn’t have time to put it on shows. If I had me some sons I might have worked on it with them, but I didn’t, I got three daughters. The car was driveable, but I didn’t have the radio or dash lights hooked up for example.”[1]

First and Last Custom

In the Army, Jim worked on vehicles and trucks, and he learned a lot. In 1967 he got a job at the Douglas Aircraft Company in Long Beach. “I worked there until I was 80 years old. From 31 years old to 80 years old. I fixed and rebuilt machinery at the factory. I loved fixing machines and stuff, and had a ball doing that! We had thousands of machines to work on." The Ford was the first and last custom Jim built. “I did a lot of stuff for guys because none of us had the money to buy new pistons and parts like that. I helped a lot of people. That’s probably a reason why I didn’t build another car.”[1]

One Man Show

Jim was a loner kind of guy, building the car himself, learning as he went along. “The magazines said that I had combined talent with my dad, but in reality, he didn’t work at it at all except for upholstering the seats and the side panels for me just because I didn’t have time before I went into the Army. My dad was a critic, and he always said “I think you can do better than that,” that’s all the help I got from him, except for the upholstery work. Dad was too busy running the upholstery shop. It was kind of neat,” Jim admits. “Because when you have the only car that looks like that, it gets noticed. I was always asked what is that? They couldn’t figure it out.”[1]

The First Lifted Custom?

The Fabulous X54 was only displayed at four shows after Jim completed the build, and if it weren’t for his dad, the story about what might be the world’s first hydraulic lifted custom would probably never have been known. “The army really screwed me up, so I was lucky that I could get it together enough for the National Roadster Show. It was a lot of hard work, but I had fun doing it! If I were building the car all over today, I would have run a power steering hydraulic pump so I could raise and lower it off the engine instead of off the battery. That would have been more practical!” Jim believes his car was the first hydraulic lifted car built to be lowered, not raised. “I don’t know anyone else that did it before me, but I don’t think much about it. Somebody once mentioned a Corvette, but I don’t know what Corvette it was or when he did it. Somebody told me that he just did the front end. I wanted to do all four corners so that I could lower the whole car. Run the back up separate. Run it in a rake. Reverse it, or do anything I wanted to. I think I was the first. Before lowriding was a Mexican thing, it was actually a Southern California American thing. Barris did it when I was a kid. Lowering cars, heating the springs!” Ron Aguirre claimed that he had lifts from a Port-A-Power tool installed on the front end of the X-Sonic Corvette at least by October of 1958. Jim’s Ford was mostly completed by October 1, 1958, and the lifts were on the car before Jim cut the roof off and fitted it with a 1957 Ford windshield.[1]

Rescued by Andy Lodi

When Jim parked the Ford, he didn't have a place to store it, so he kept it at his dad’s shop until the supermarket one day wanted to take half a block. “By taking half a block, I could do nothing but covering it up from the elements. I stored it outside next to my dad’s 1937 Hudson Terraplane pick up. Things happened, and I had another life. After a while the car got rusted, and the plastic separated from the metal.” Around 2000 the city eventually demanded Jim to remove the Ford and several other vehicles he stored on his property. When Jim had to remove the cars, he called Andy Lodi and asked if he was interested in buying the old custom. Andy, who had been trying to buy the car for years jumped at the opportunity to save this milestone custom car. Andy was first exposed to hydraulic lifted cars in 1968, and he went on to form Adex, a company that specialized in “Square Dumps” for aircraft hydraulic set ups. Andy was going to restore the Ford, so Jim gave him a couple of 1956 Ford two-door hardtops he could use for parts, as they had the same suspension. “I told Andy he would be better off if he took the body completely off and put a body that isn’t so rusted out and build from that.”

Sold to Bryan Robinson at Bellflower House of Style

Busy with his seven children, Andy decided to pass on the project in 2015, and he sold it to Bryan Robinson of Bellflower, California. Bryan runs Bellflower House of Style, a custom paint and art store focusing on the old school style of customs from the 1950s and the 1960s. In 2019 Bryan told Sondre Kvipt that he wants to do a complete restoration of the car, restoring it back to how it appeared when it was first built in 1958. “It is still complete and untouched. I have three of the original tires with tubes, and all hydraulics are there as built in 1957.” If everything goes as planned, Bryan will start the restoration in 2019.[2]

Magazine Features and Appearances

Custom Cars February 1959

Custom Cars July 1959

Customs Illustrated September 1959

Trend Book 189 Custom Cars 1960 Annual

Gasoline Magazine 3/2018

V8 Magazine 1/2021

References

Did you enjoy this article?

Kustomrama is an encyclopedia dedicated to preserve, share and protect traditional hot rod and custom car history from all over the world.

- Help us keep history alive. For as little as 2.99 USD a month you can become a monthly supporter. Click here to learn more.

- Subscribe to our free newsletter and receive regular updates and stories from Kustomrama.

- Do you know someone who would enjoy this article? Click here to forward it.

Can you help us make this article better?

Please get in touch with us at mail@kustomrama.com if you have additional information or photos to share about Jim Logue's 1954 Ford.

This article was made possible by:

SunTec Auto Glass - Auto Glass Services on Vintage and Classic Cars

Finding a replacement windshield, back or side glass can be a difficult task when restoring your vintage or custom classic car. It doesn't have to be though now with auto glass specialist companies like www.suntecautoglass.com. They can source OEM or OEM-equivalent glass for older makes/models; which will ensure a proper fit every time. Check them out for more details!

Do you want to see your company here? Click here for more info about how you can advertise your business on Kustomrama.